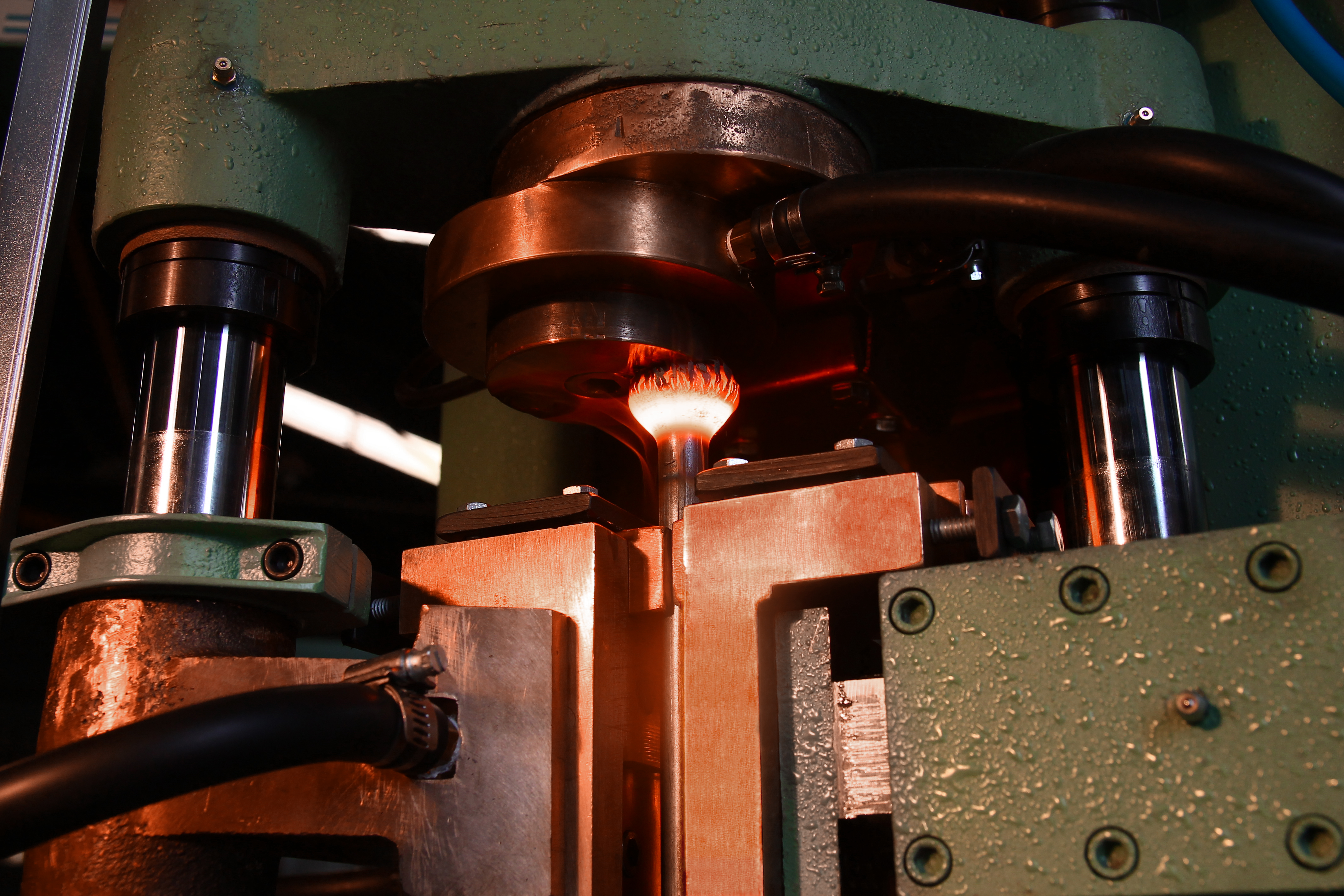

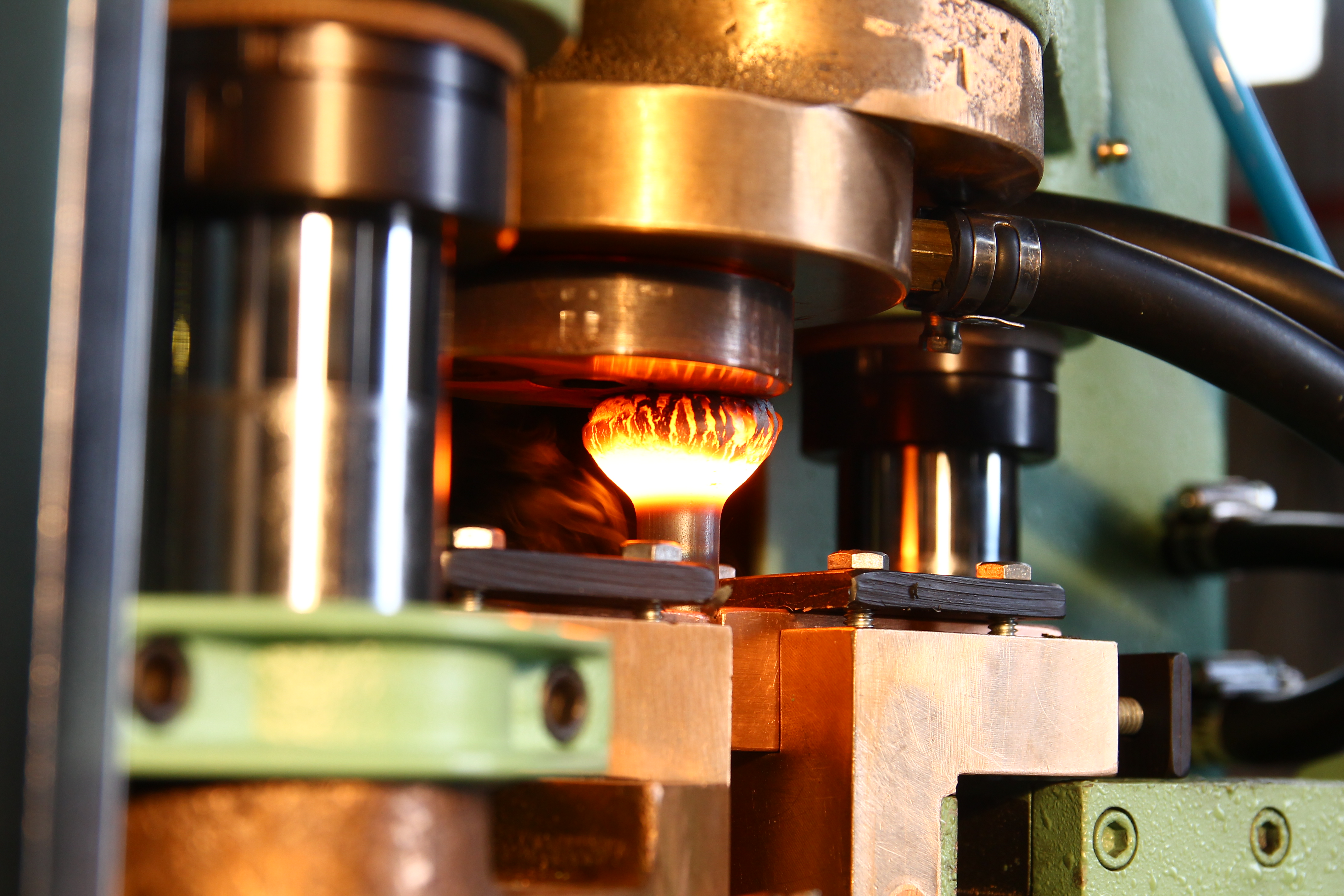

Vertical Pneumatic Electroforging Machines

General description

These machines are built in a vertical or horizontal disposition. Principal movement is made over cylindric chrome treated cylinders, mounted over fundition headers, located over a 5mm thick steel plate. Every movement is controlled by electrovalve driven, speed regulated pneumatic cylinders. Meanwhile, the anvil is made of a Hydropneumatic unit, which yields the hydraulic control and the pneumatic simplicity. Copper alloy clamp holders are water cooled. Transformer designed with the most advanced techniques, to achieve the maximum performance. Made of mimimum losses (1.4W/Kg) silicon forged steel and coiled entirely with electrolitic copper, water cooleed. Heating capacity: 2-3 Kg/KWh; Power consumption: 0,35 - 0,50 Kwh / Kg heated material. This machines start cycle is fast and simple. Just power up, set compressed air supply at 7 Kg/cm2 (they are provided with their own FRL protective unit) and connect tap water or closed circuit tower cooling system.

Optionals

- Two central zone forge clamps.

- Transformer power electronic control, with level and ramp regulation.

- Custom designs on demand.

Technical features

| MODEL | RNV 15 | RNV 25 | RNV 40 |

|---|---|---|---|

| Transformer Power Kva | 15 | 25 | 40 |

| Trasformer regulator: | 16 high positions y 16 low positions | ||

| Forging bar diameter mm. | 3 - 14 | 5 - 9 | 10 - 25 |

| Forging bar max lenght, Standard mm | 750 | 750 | 750 |

| Special mm | 1250 | 1250 | 1250 |

| Forging lenght mm | 170 | 245 | 245 |

| Max heating capacity Kg/h | 18 - 25 | 30 - 40 | 50 - 65 |

| Input Energy Kwh | 6-9/8-12 | 10-15/14-20 | 17-25/21-32 |

| Limit Dimensions Width x Height mm | 900x2100 | 900x2100 | 990x2100 |

| Depth mm | 860 | 860 | 970 |